Reneos: the European tailor-made solution for end-of-life batteries

Reneos is a European network specialising in the collection and recycling of batteries, and offering tailor-made solutions. Read more about it here

If it wasn’t for recycling, the electric vehicle future would be doomed. The industry is growing hyperfast, and battery demand will soon outpace the supply of raw materials from natural sources. Therefore, in order to keep up the EV momentum, we need to shift our focus to an alternative ‘mining’ technique: lithium-ion battery recycling*.

But how exactly does that work? How do recyclers recover the raw materials from your discarded battery cells? Which steps are required to prepare the elements for reuse? In this article Reneos gives you an exclusive look behind the scenes of the recycler, from the moment your batteries get collected.

* In general, recycling becomes the preferred option after the possibilities of ‘second use’ have been exhausted.

In order to keep up the EV momentum, we need to shift our focus to an alternative ‘mining’ technique for raw materials: lithium-ion battery recycling.

For this year (2020), the global battery demand is estimated at 282 GWh. The expectation is that by 2030, this figure will rise to 3.500 (!) GWh. Given that there won’t be enough lithium, cobalt and nickel to support such intense growth, we better step up the recycling game.

That’s why future-minded recycling companies are fully engaged in developing the most efficient recycling methods for EV batteries, and recover as much of the raw material as possible.

So what does the recycling process look like? Depending on the recycler, a battery’s journey may take slightly different routes, but in general there are three big stages. Let us guide you through the process, step by step.

After your lithium-ion batteries have been collected, their first stop is the dismantling department. A team of high-voltage dismantlers prepares the battery for recycling by disassembling the battery pack into single components: case, cathode, anode, electrolyte, separator and binder. The components get deactivated to minimise the risks of reactions during the recycling process.

In this stage of ‘mechanical processing’ there is a recovery of iron, copper foil, aluminium foil, the separator and coating materials, but further refinement by pyro- and/or hydrometallurgy is required.

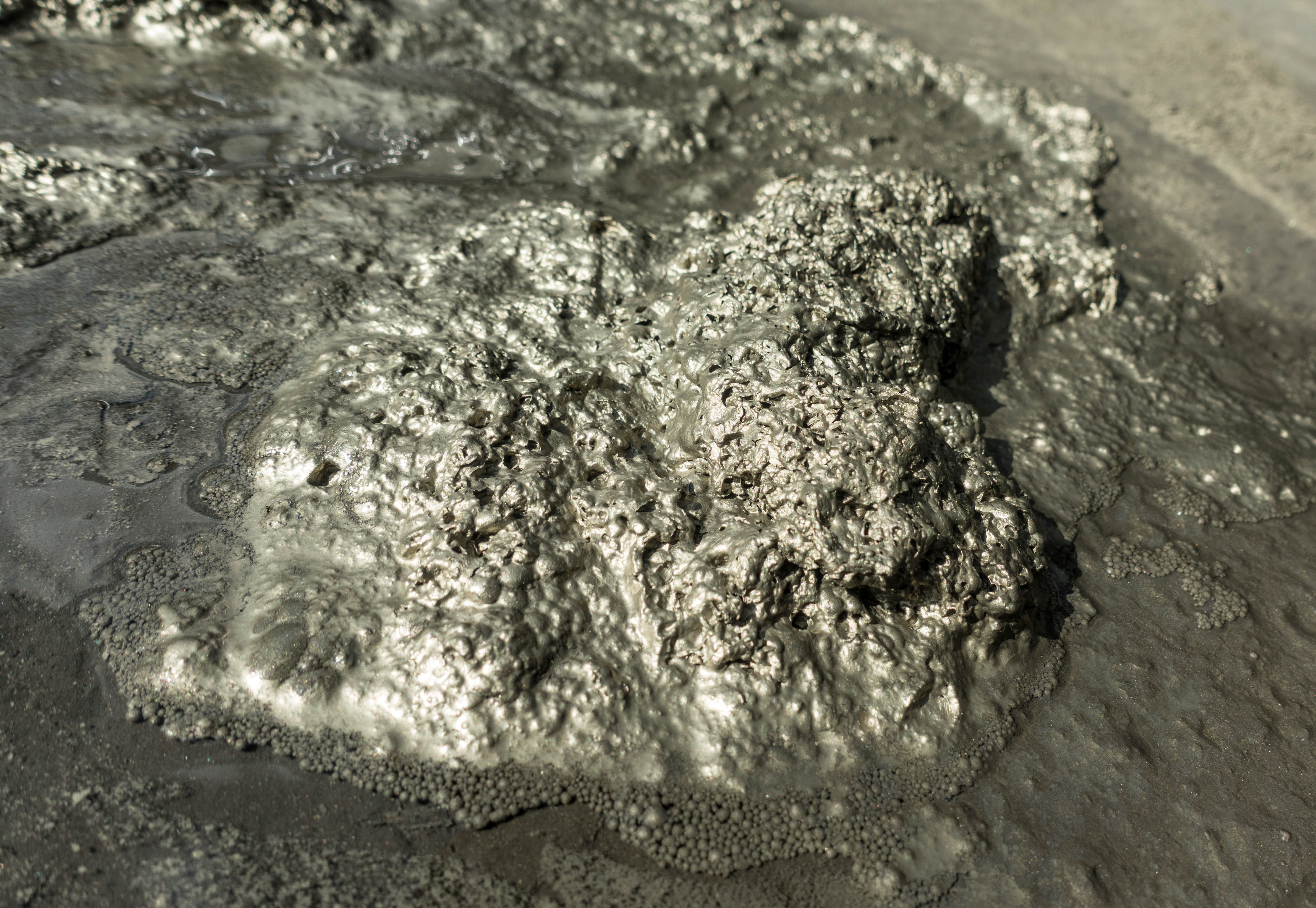

The next stage is where the magic happens. This is where the valuable materials of the battery components get extracted.

Certified recycling companies of Reneos’ national collection partners perform one or both of these treatments on the battery components:

Every recycling company has its own unique procedure. Some use both methods in combination with the mechanical processing from the first step, while others only use one. The approach they choose depends on the materials they aim to recover, and what ‘recycling efficiency’ they are setting out to achieve.

According to a recent study on lithium-ion battery recycling methods, “only processes employing a combination of mechanical processing and hydro- and pyrometallurgical steps seemed able to obtain materials suitable for LIB (re)manufacture” (Velázquez-Martínez et al., 2019). Whereas processes relying on pyrometallurgy are only capable of recovering metallic components.

The materials that result from pyrometallurgical processing are separated fractions of iron, aluminium or copper. However, these don’t come out in the 100% pure form that is needed for reuse. That's why there is a final step to the recycling process: purification. In this stage, the materials are treated by specialised smelters, who are able to get the elements back to their purest form.

After a successful recycling process, the obtained raw materials are ready to be injected back into the economy. Recovered iron, aluminium, copper, cobalt, nickel and other materials can now be used for the production of new applications. What happens to them is up to the recycler, but as the EV market is on the rise, it is very likely that the elements of the batteries you enter into the recycling process will find their use in brand new lithium-ion batteries. That’s the circle of battery life that makes the EV future possible.

Are you ready to fulfill your recycling duties? At Reneos, we are happy to help. Our commitment to you is that we will always find the most efficient recycling strategy for your lithium-ion batteries all across Europe, thanks to our large network of certified partners. You are able to follow the entire process on one platform, with one single point of contact, and receive one invoice.

Find out what Reneos can do for you:

>> Download the information brochure

Sources: